- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-02-16 Origin: Site

Air filtration plays a vital role in ensuring the quality of air in various environments, from homes and offices to industrial settings. One of the most effective and widely used types of air filters is the pleated filter. These filters are designed to offer superior filtration efficiency by increasing the surface area available for capturing contaminants. Whether in HVAC systems, cleanrooms, or industrial air filtration systems, pleated filters are essential for maintaining clean and healthy air.

In this article, we will delve into the entire manufacturing process behind pleated filters. From selecting the right materials to assembling the filter components, understanding how pleated filters are made can help you appreciate their effectiveness and why they are a smart choice for air filtration needs.

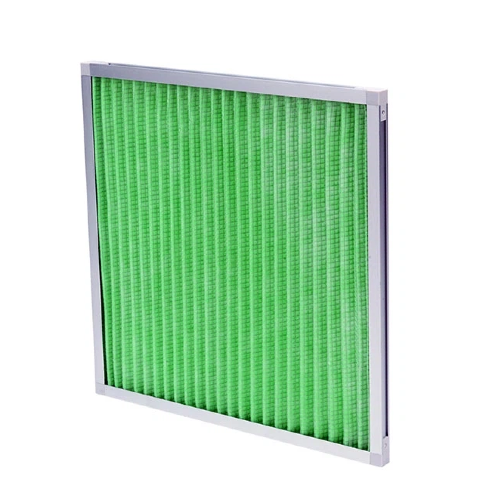

A pleated filter is a type of air filter with a unique folded design, typically made from synthetic materials, fiberglass, or a combination of both. The pleats, or folds, increase the surface area of the filter media, allowing it to capture a larger volume of particles and contaminants compared to traditional flat filters. This design not only enhances the filter's ability to trap dust, dirt, pollen, and other airborne pollutants but also helps in maintaining low airflow resistance.

The increased surface area is a key advantage of pleated filters, enabling them to hold more debris and extend the time between replacements. This makes them highly efficient and durable, offering superior performance in maintaining clean air. Whether used in residential HVAC systems, industrial air filtration setups, or specialized environments like cleanrooms, pleated filters are designed to meet the demands of both high and low filtration needs.

Compared to flat filters, pleated filters provide a more efficient solution, especially in settings where air quality is essential, offering a longer lifespan and better overall air filtration performance.

The filter media is the most critical component of a pleated filter. It determines the filter's ability to capture particles and contaminants from the air. The most commonly used materials for filter media in pleated filters include:

Polyester: This synthetic material is durable and commonly used for pleated filters due to its ability to capture dust, dirt, and other particles effectively.

Fiberglass: Known for its lightweight nature, fiberglass is used for filters that need to perform under high airflow conditions.

Synthetic fibers: Synthetic materials, such as polypropylene, are increasingly used for pleated filters as they are resistant to moisture and bacteria, enhancing the filter's durability in humid environments.

The frame holds the filter media in place and provides structure to the pleated filter. The most common frame materials include:

Cardboard: Often used for disposable filters, cardboard frames are cost-effective and lightweight, but they are generally not as durable as other options.

Aluminum: Lightweight and highly durable, aluminum frames are used for reusable pleated filters, providing long-term reliability.

Galvanized steel: Steel frames are used for heavy-duty industrial filters, providing strength and durability in harsh environments.

Some pleated filters include supporting layers that help maintain the integrity of the pleats. These layers prevent the media from collapsing under pressure, ensuring the filter's efficiency over time. Supporting layers are typically made from mesh materials, which help to provide structure without compromising airflow.

The first step in manufacturing a pleated filter is preparing the filter media. Depending on the material selected, the media may be treated or coated to enhance its filtration capabilities. For instance, polyester media might be treated with a dust-repelling coating, while fiberglass media is often layered for increased efficiency.

The media is then cut into sheets, which will be pleated to increase surface area. This is an essential step in ensuring the filter's effectiveness in capturing particles from the air.

Once the media is prepared, it is subjected to the pleating process. Pleating involves folding the media into a series of evenly spaced folds, increasing the surface area significantly. The pleating machine carefully folds the media to achieve consistent pleats, ensuring uniform airflow and maximum filtration efficiency.

The depth of the pleats and the spacing between them is carefully controlled during this step to ensure that the filter performs optimally. The pleats must not be too close together, as this can restrict airflow, nor too far apart, as this could reduce the filter’s efficiency in capturing particles.

After the pleating process, the pleated media is inserted into a frame. The frame holds the pleats in place and provides the necessary structure for the filter. The media is secured within the frame, and any additional layers of mesh or supporting materials are added to reinforce the pleats.

The frame edges are sealed to prevent air from bypassing the filter and to ensure that the media stays firmly in place. The filter is then cut to the required size, depending on the specific application it is intended for.

Before a pleated filter is released for distribution, it undergoes several rounds of testing and inspection. Each filter is checked for:

Airflow resistance: The filter should allow air to pass through with minimal resistance.

Filtration efficiency: Filters are tested to ensure they can capture particles of various sizes effectively.

Structural integrity: The pleats should be stable, and the frame should hold the media securely without any signs of damage.

Once the filter passes all tests, it is packaged and prepared for shipment to distributors or end customers.

These are designed for one-time use and are typically used in residential HVAC systems. After a few months of use, disposable filters are replaced with new ones. These filters are often made from cardboard frames and can be found in various sizes, making them suitable for different HVAC systems.

Reusable pleated filters are designed for industrial and commercial applications, where the filters need to last longer and handle higher airflow. These filters often feature aluminum or galvanized steel frames and can be cleaned and reused multiple times before they need to be replaced.

These filters are designed for specialized environments, such as hospitals, cleanrooms, and laboratories, where high levels of filtration are required. High-efficiency pleated filters typically have a MERV rating of 12-16 and are capable of trapping very fine particles, including bacteria and viruses.

Filter Type | Application | Frame Material | MERV Rating | Common Use Case |

Disposable Pleated Filter | Residential HVAC | Cardboard | 6-8 | Standard home HVAC systems |

Reusable Pleated Filter | Industrial/Commercial HVAC | Aluminum/Galvanized Steel | 8-12 | Industrial air filtration |

High-Efficiency Pleated Filter | Hospitals, Cleanrooms | Aluminum/Galvanized Steel | 12-16 | High-efficiency air filtration |

The pleated design provides a larger surface area for capturing contaminants. This allows pleated filters to trap more particles without significantly increasing the pressure drop, ensuring efficient airflow.

Manufacturers use high-quality materials for the filter media and frame to ensure the pleated filter lasts longer and performs consistently. The use of durable materials helps prevent the filter from collapsing under high airflow conditions.

Pleated filters are designed to capture a wide range of particles, from large dust particles to tiny allergens and bacteria. The increased surface area allows the filter to capture more contaminants without reducing airflow.

In conclusion, pleated filters are an excellent choice for efficient and durable air filtration. Their unique design increases surface area, enhancing filtration while maintaining optimal airflow. The manufacturing process involves careful material selection, precise pleating, and rigorous testing to ensure top performance across various applications. Whether for residential HVAC systems, industrial air filtration, or specialized cleanroom environments, pleated filters play a critical role in maintaining clean and healthy air.

At GUANGDONG VITE AIR CLEAN SYSTEM CO., LTD., we specialize in providing high-quality pleated filters that meet the demands of different air filtration systems. With our commitment to precision and performance, we offer solutions tailored to enhance air quality and system efficiency. For more information or to explore our range of pleated filters, we invite you to contact us. Let us help you find the ideal filtration solution for your needs.

Q1: What materials are pleated filters made of?

A1: Pleated filters are typically made from materials such as polyester, fiberglass, or synthetic fibers for the filter media. The frame is usually made from cardboard, aluminum, or galvanized steel, depending on the type of filter.

Q2: Why is the pleated design important in a filter?

A2: The pleated design increases the surface area of the filter, allowing it to capture more particles efficiently while maintaining low airflow resistance. This makes pleated filters more effective than flat filters.

Q3: How are pleated filters tested during the manufacturing process?

A3: Pleated filters undergo several tests to ensure they meet performance standards, including airflow resistance tests, filtration efficiency tests, and structural integrity checks.

Q4: How long do pleated filters last?

A4: Pleated filters typically last longer than non-pleated filters. Disposable filters need to be replaced every 3-6 months, while reusable filters can last for several years with proper cleaning and maintenance.