Premium Bag Filter Solutions & Materials: Engineered for Peak HVAC & Cleanroom Performance"

Bag filters, also known as pocket filters, is the most common air filters in HVAC systems for industrial and commercial applications to improve indoor air quality. The filters are used as first and second filter stages, either as complete filtration solutions for these applications or as prefilters for cleanroom process applications.

Bag filter(F5-F9) is consist of metal/plastic frame and bag filter media mainly, filter depth range is 290-760mm,and width and Length is 595*595mm usually.

Obviously, high-quality raw material is the key to obtaining high-quality bag filters. In VTF, we not only make finished product, also produce the raw materials , include the bag filter rolls and related crucial materials meltblow fabric and PP&PET composite media.

Our deep material expertise ensures every finished bag filter delivers on its promise of performance and value.

Bag Filter

Filter Media

Raw Material Advantages & Manufacturing Process

Material Variety:

Includes PP melt blown fabric, PP\&PET composite media, and bag filter rolls/pads.

Imported Production Lines:

Two advanced lines for PP melt blown and PP\&PET composite media and three lines for bag filter rolls/pads

High Production Capacity:

Capacity of up to 3 tons per day for fabric media.

Bag Filter Roll Production:

Three lines for bag filter rolls/pads, producing 10,000 meters per day.

Quality Assurance:

Materials meet EN779 standard, ensuring high efficiency and resistance.

Testing Process:

Rigorous testing on efficiency and resistance before material delivery.

Consistent Supply:

Reliable, high-quality products for optimal customer satisfaction.

Quality Control & Product Testing

Strict Compliance & Testing

All materials are produced in accordance with EN779 standards. Efficiency and resistance are rigorously tested before delivery to ensure high-quality performance.

Tailored Material Selection & Production

Materials are carefully chosen and customized through advanced manufacturing techniques to meet specific customer requirements, ensuring optimal filtration performance.

Reliable Durability & Consistency

The production process guarantees consistent material performance, offering long-lasting durability and reliable filtration under various operational conditions.

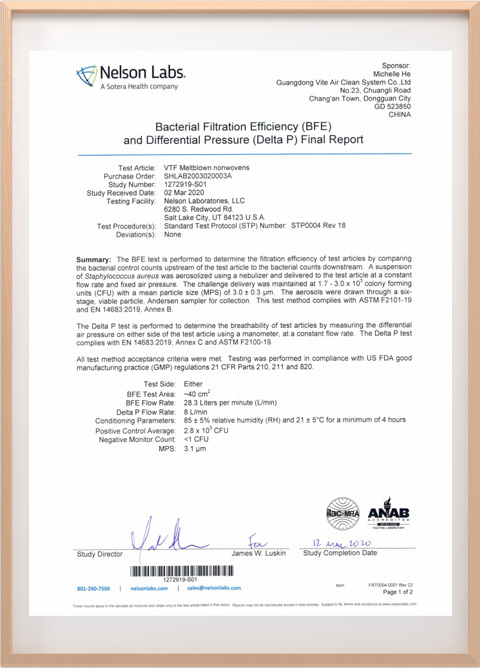

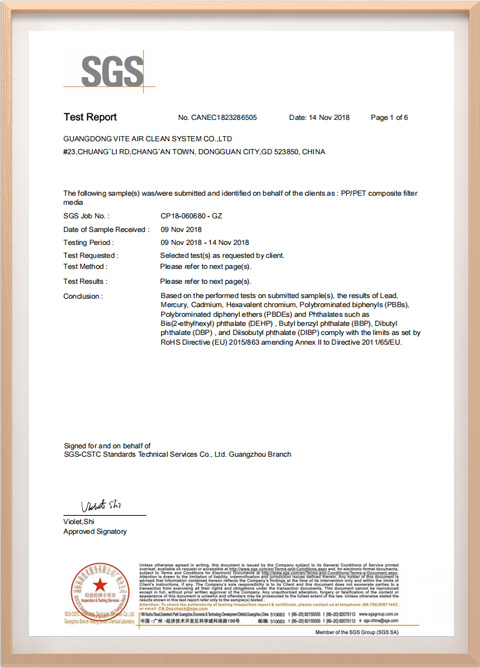

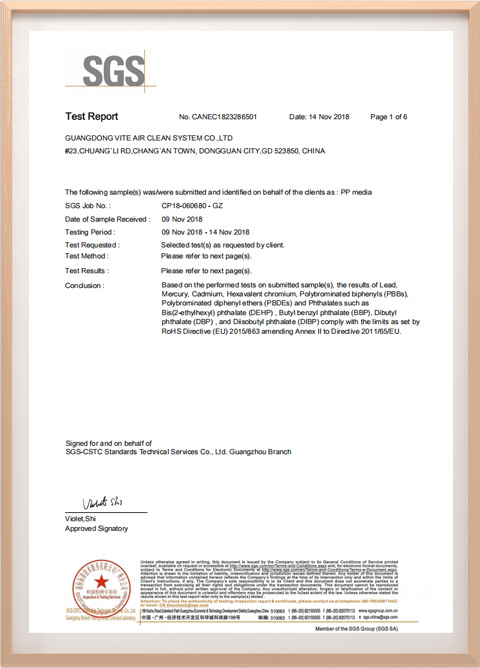

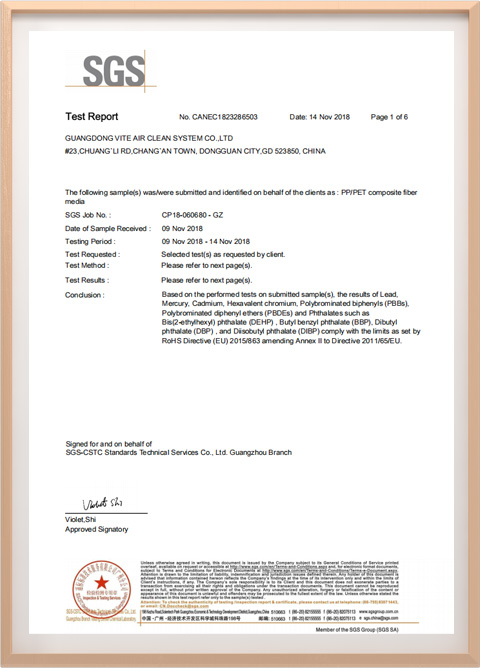

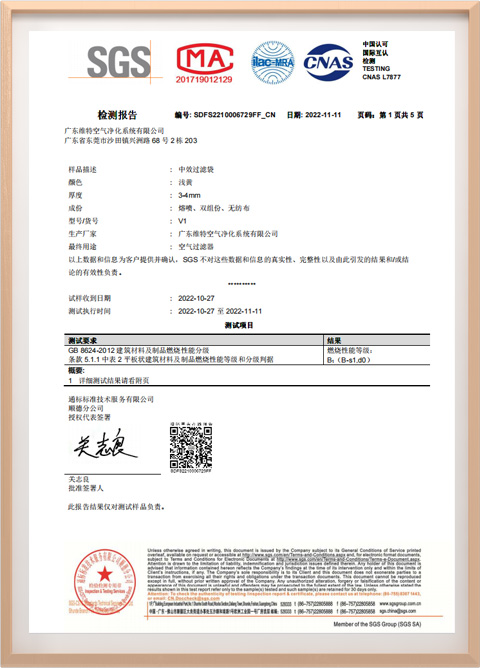

Certificates

Our products are certified to meet global standards, ensuring superior quality, reliability, and performance. We prioritize customer satisfaction with top-tier service and exceptional product advantages.

Keep In Touch with Us

Contact Information

For further information, please reach out to our customer service team for personalized assistance.

TEL

+86-769-8544-0538

English

English